Precision and Excellence in Plastic Injection Molding: Why Executool is a Leader in the Industry

In today’s fast-paced manufacturing world, industries rely on precision, efficiency, and innovation to deliver top-quality products. Executool Precision Tooling is at the forefront of this movement, providing specialized plastic injection molding services with unmatched expertise and commitment to excellence.

The Importance of Precision in Plastic Injection Molding

Plastic injection molding is a critical process for industries such as automotive, electronics, medical devices, and consumer goods. It involves shaping plastic into precise, functional components that meet specific tolerances and design requirements. The need for accuracy and reliability in these parts is paramount, as even the smallest deviation can lead to costly errors, product failures, or production delays.

At Executool, we understand the demands of modern manufacturing and have fine-tuned our processes to ensure that every mold we create adheres to the strictest quality standards. Our team specializes in producing close tolerance molds, ensuring that every product not only meets but exceeds client expectations.

Comprehensive Services from Concept to Final Product

One of the key strengths of Executool is our ability to manage every stage of the injection molding process. From initial CAD design to the final production stage, we provide end-to-end solutions that ensure consistency and efficiency.

- Design & Engineering Support: Our team of experienced engineers works closely with clients to design molds that are optimized for production. Using advanced CAD software, we develop detailed 3D models, ensuring the mold is designed for longevity, cost-effectiveness, and accuracy.

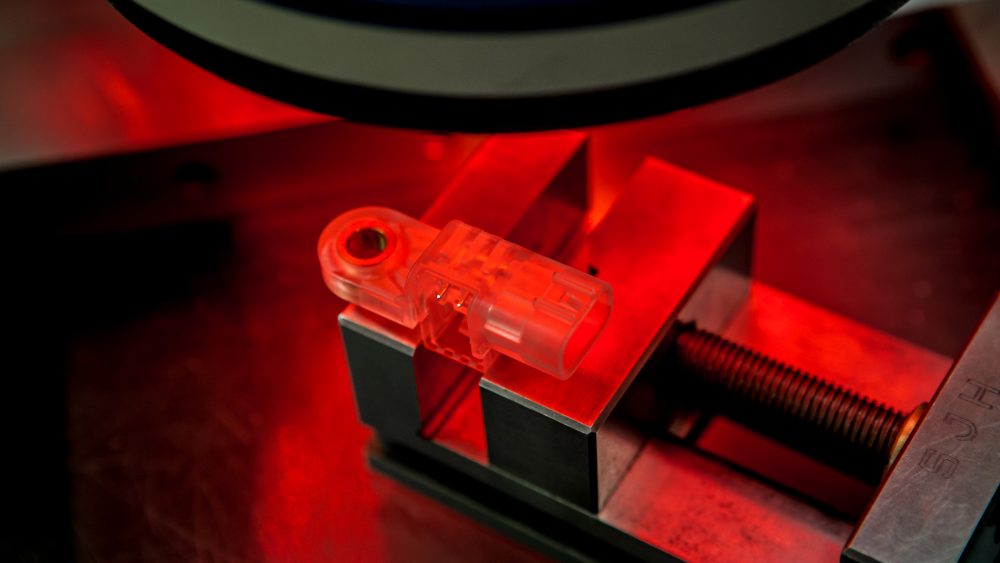

- Precision Mold Manufacturing: Once the design is finalized, our precision tooling division takes over, utilizing the latest CNC machines and other state-of-the-art equipment. The result is a mold that offers exceptional durability and dimensional accuracy, even for the most complex designs.

- Injection Molding Production: With the molds ready, our injection molding process ensures that the final products are consistently of high quality. We work with a variety of thermoplastics to create parts that are customized to the specific needs of each industry. Whether it’s a high-volume run or a specialized batch of products, Executool delivers with efficiency.

- Repair & Maintenance Services: We also offer comprehensive repair and maintenance services for molds. This extends the lifespan of the mold and ensures minimal downtime in your production line, making Executool a valuable long-term partner.

Industries We Serve

At Executool, we pride ourselves on being able to adapt to the unique needs of various industries. Some of the sectors we serve include:

- Automotive: We create durable, high-performance components that are integral to vehicle safety and functionality.

- Medical: We deliver precision parts that are compliant with stringent healthcare regulations, ensuring reliability for medical devices and tools.

- Electronics: Our molds are used to manufacture intricate parts that are essential for modern electronics, from smartphones to home appliances.

Why Choose Executool?

- Experience & Expertise: With decades of experience in the field, Executool has established itself as a leader in plastic injection molding. Our highly skilled team brings unparalleled knowledge to every project.

- Cutting-Edge Technology: We invest in the latest manufacturing technology to ensure precision and quality. From CAD software to advanced CNC machines, we use top-tier tools to stay ahead of the competition.

- Customer-Centric Approach: We understand that each client’s needs are different, and we offer customized solutions that meet those requirements. From the design phase to final delivery, we work closely with our customers to ensure complete satisfaction.

Looking to the Future: Sustainability and Innovation

At Executool, we believe in the importance of sustainable manufacturing practices. We are constantly exploring ways to reduce waste, optimize resource use, and incorporate eco-friendly materials into our processes. As industries evolve, so do we, with a focus on innovation that embraces both technological advancements and environmental responsibility.