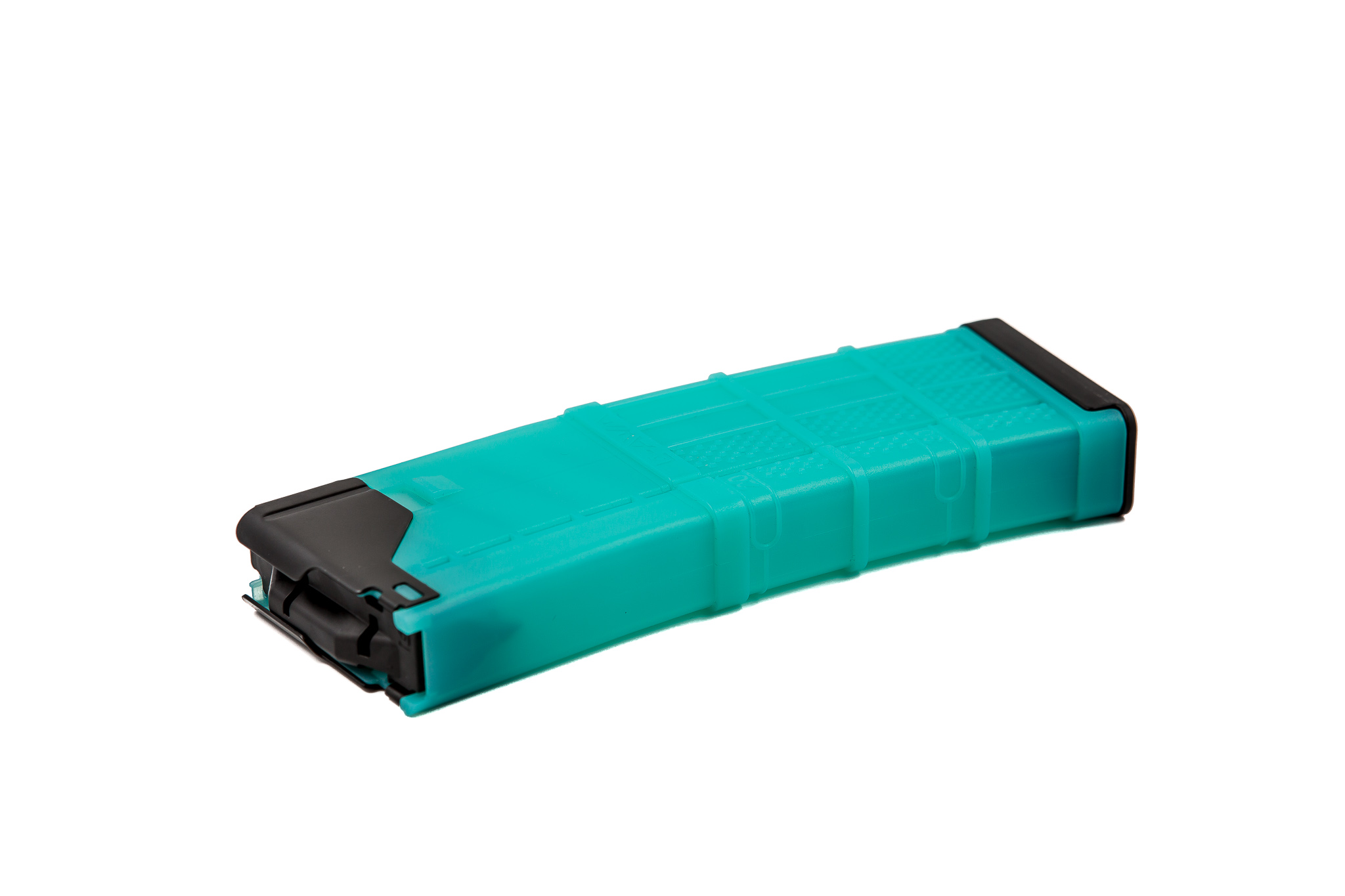

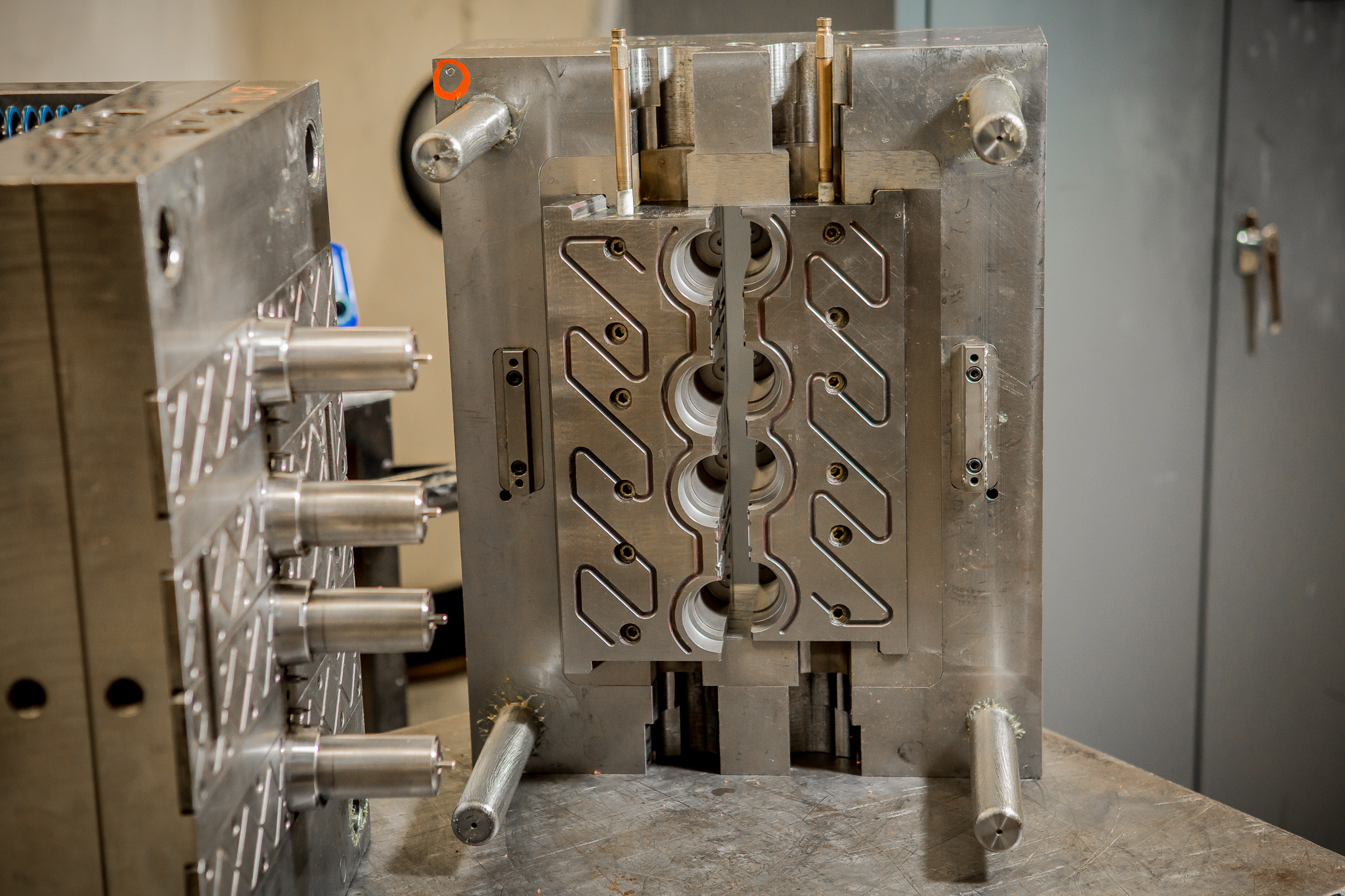

Molding: Production Capabilities

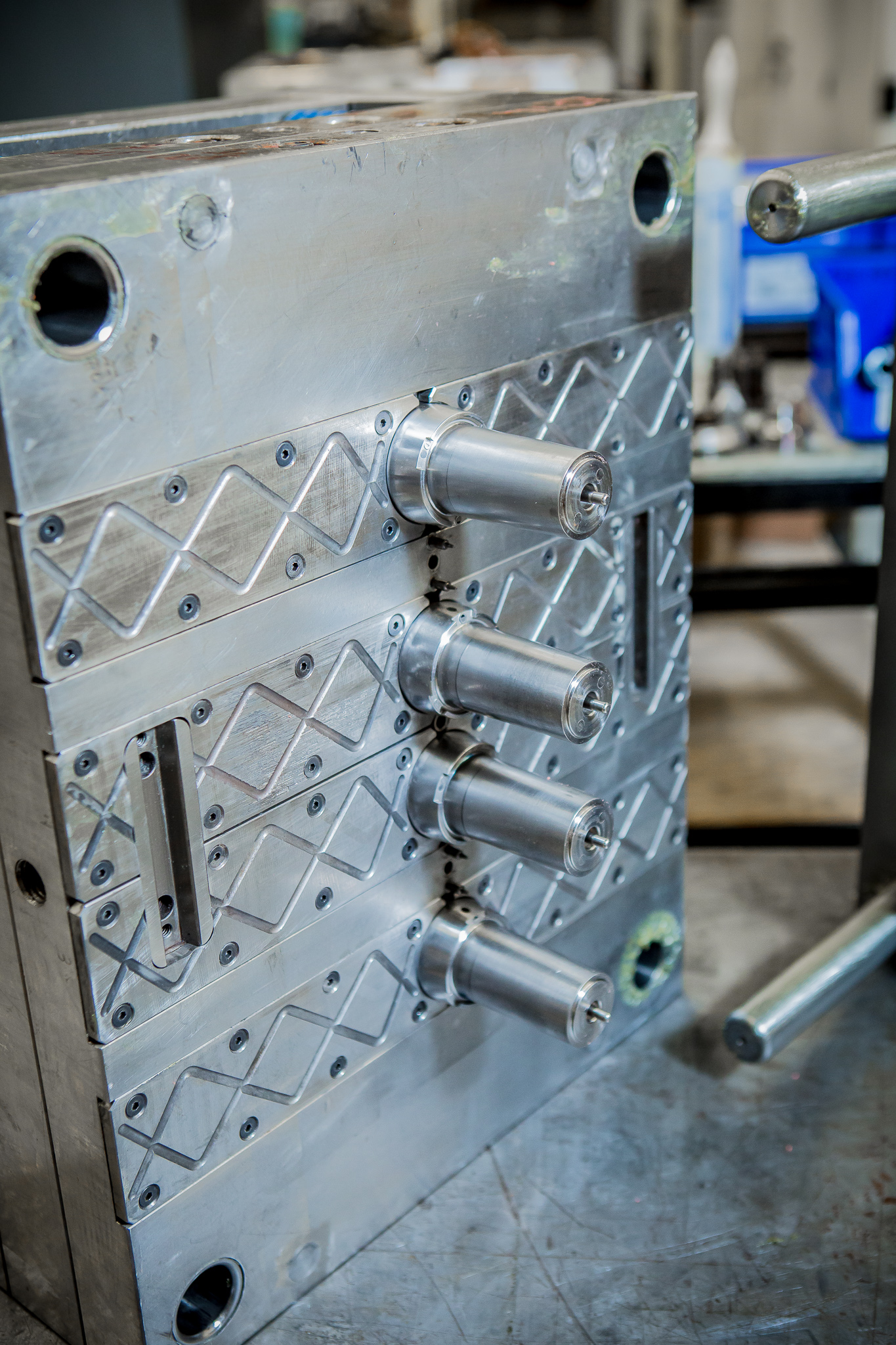

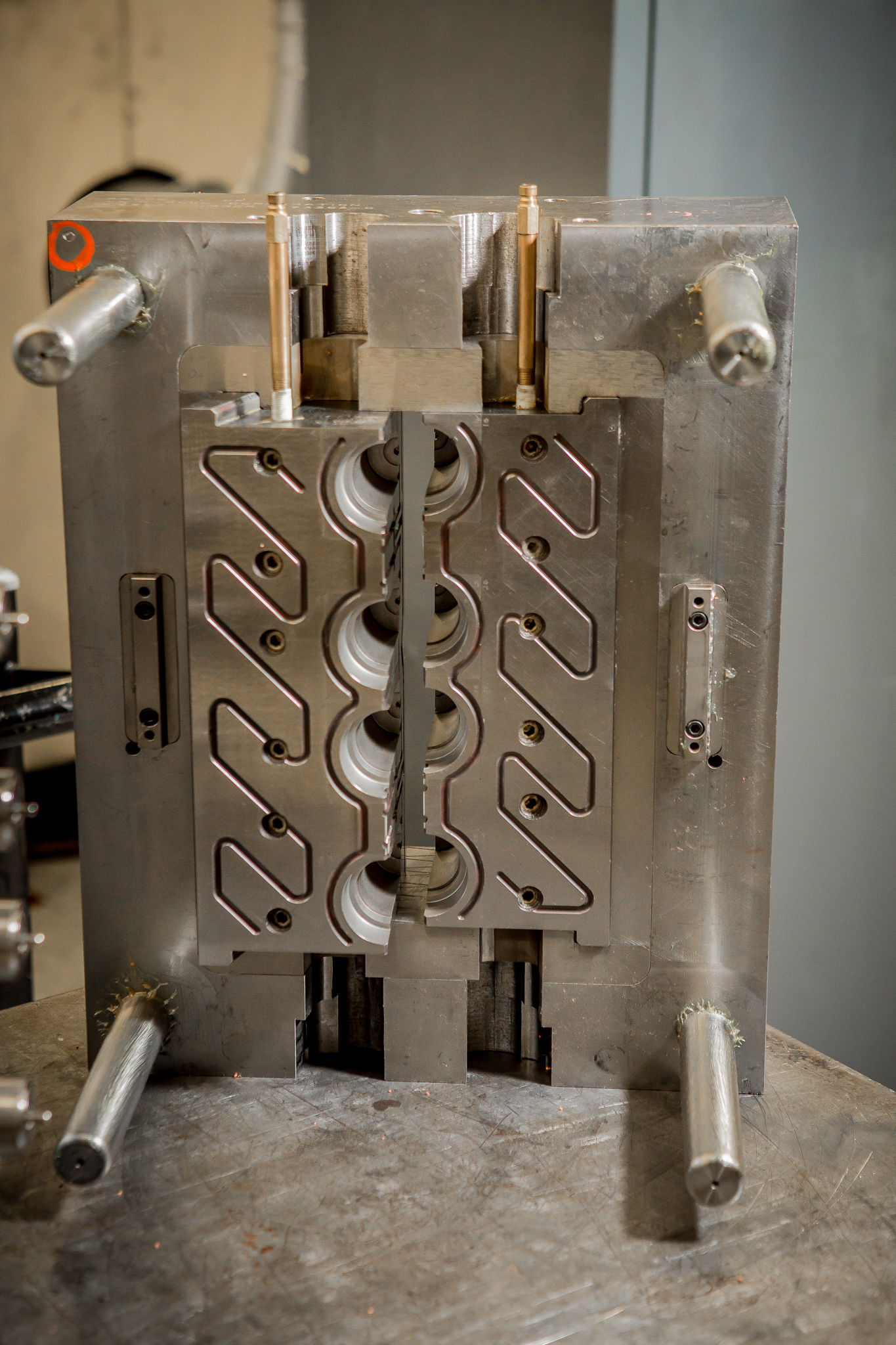

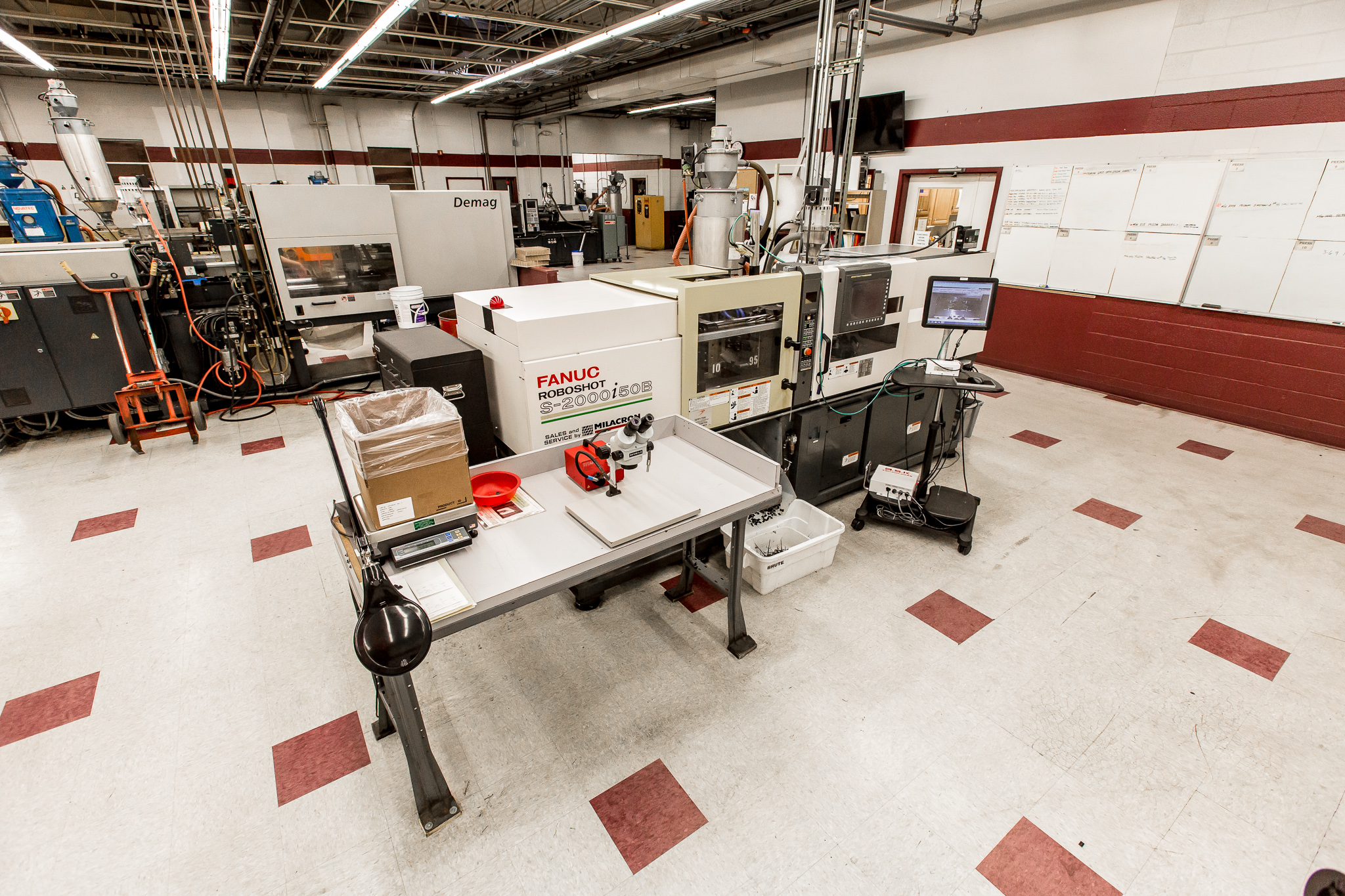

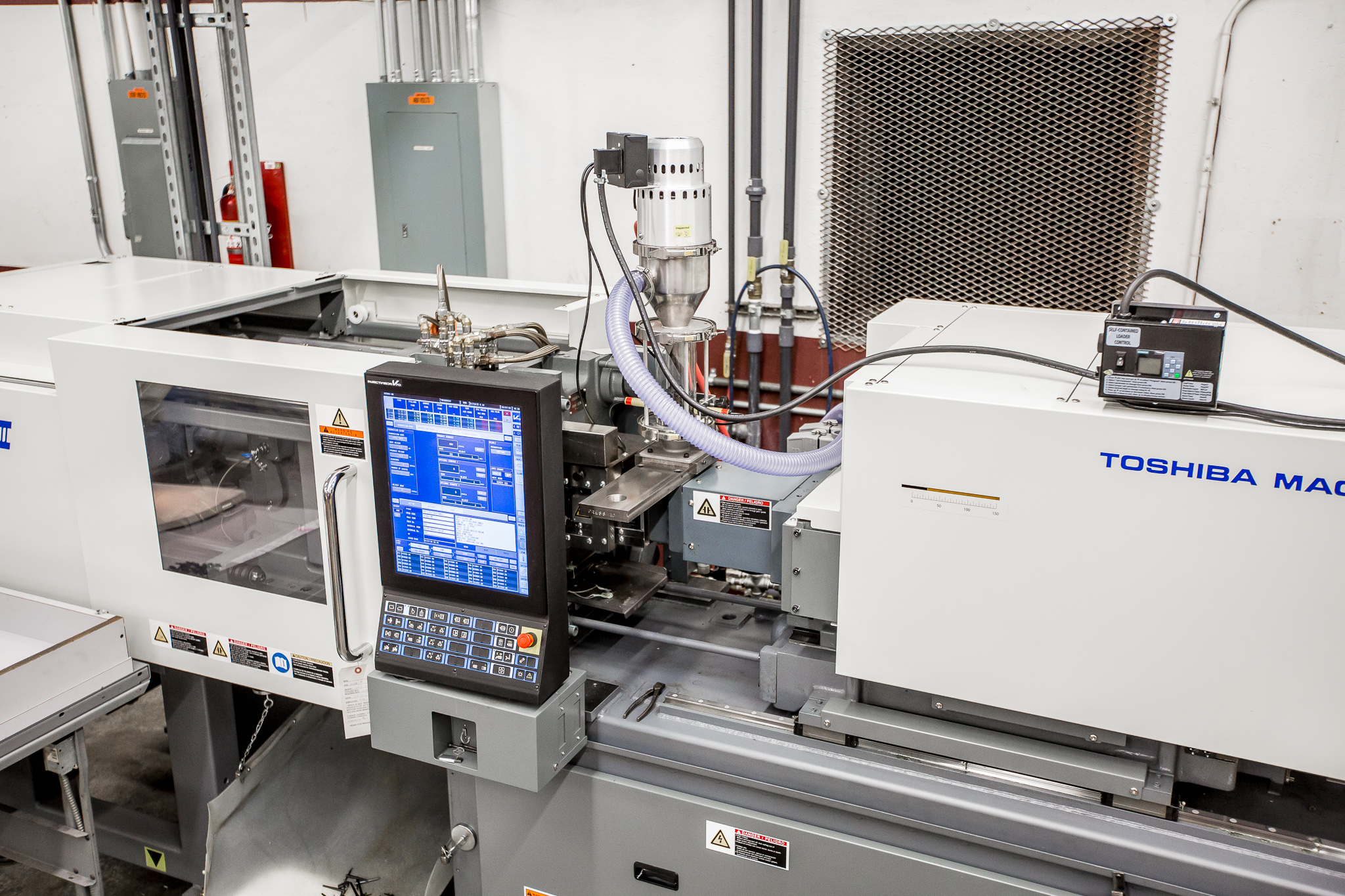

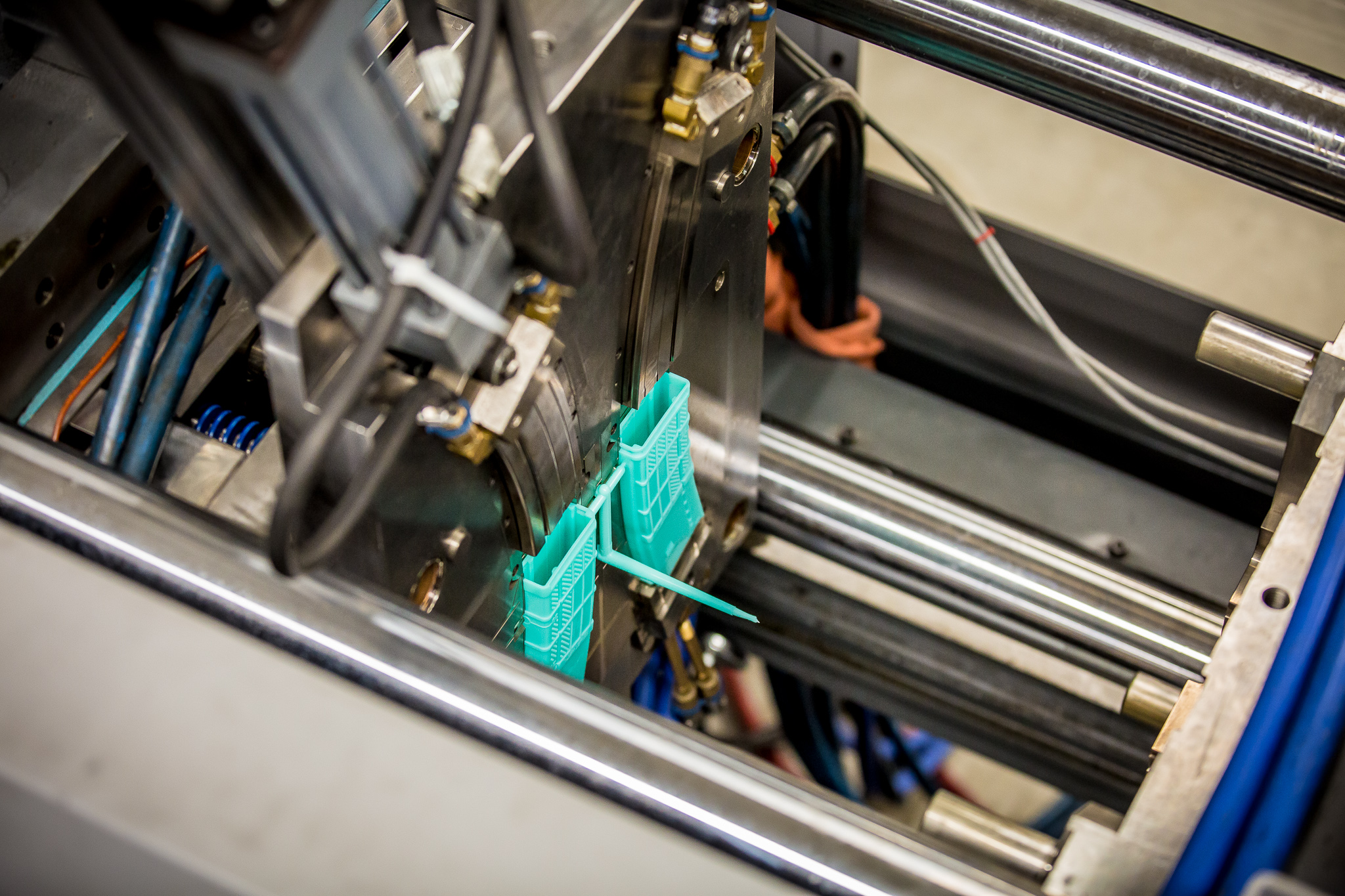

Executool is a world-class custom injection molder, specializing in tight tolerance of engineering-grade resin polymers. Capabilities range from prototype tooling and material sampling to single-/multi-cavity production capacity. We are ITAR, ISO 9001 and ISO 13485 certified and continue to build upon our reputation for exceptional quality and attention to detail. Our 15,000-sq.-ft. Molding Department is a 24-hour production facility, with a wide variety of presses that range in size from 17 to 200 tons. We use close-looped molding machines, with barrel capacities of .46 to 14 oz., that allows for high-precision repeatability.

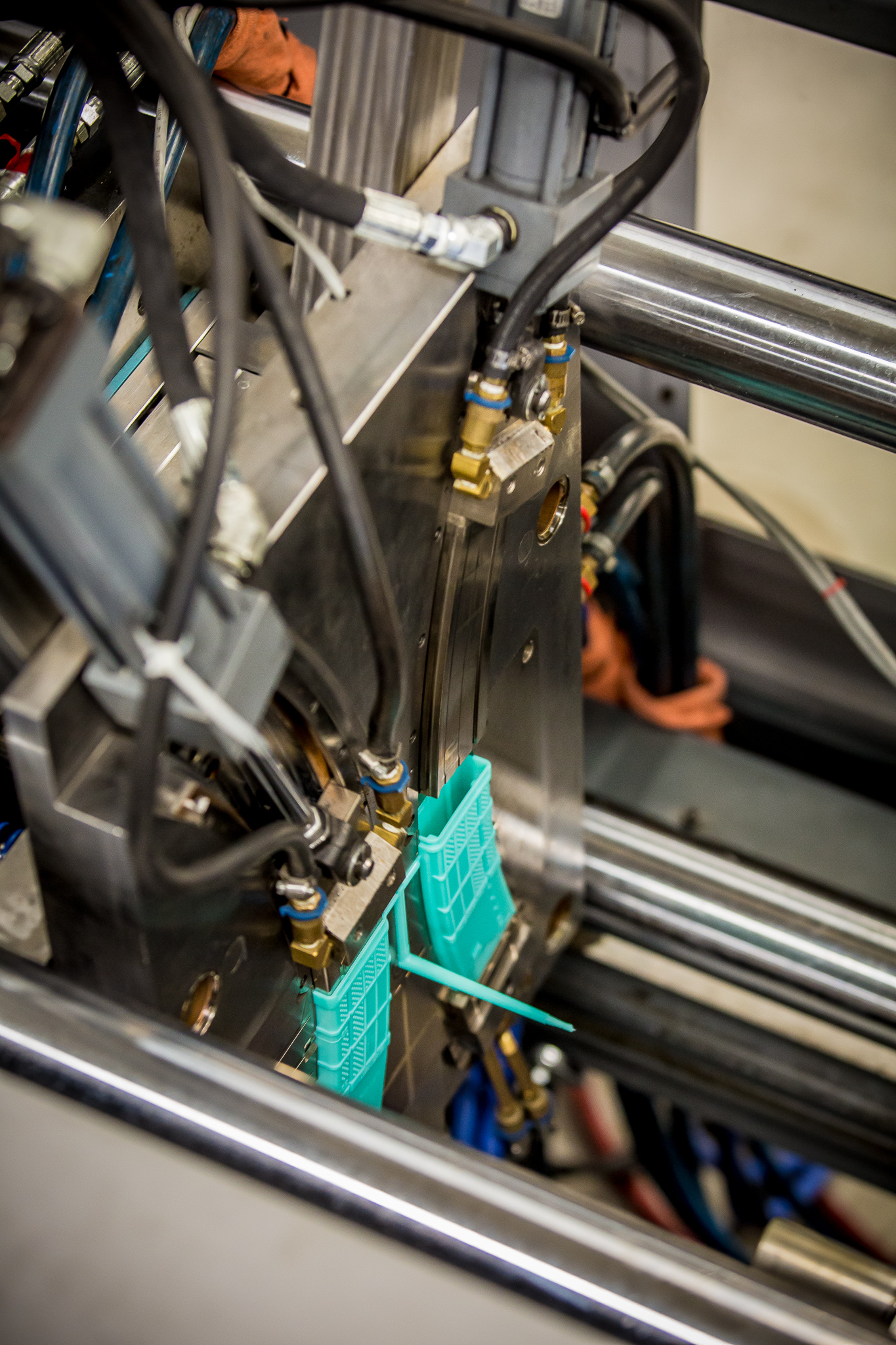

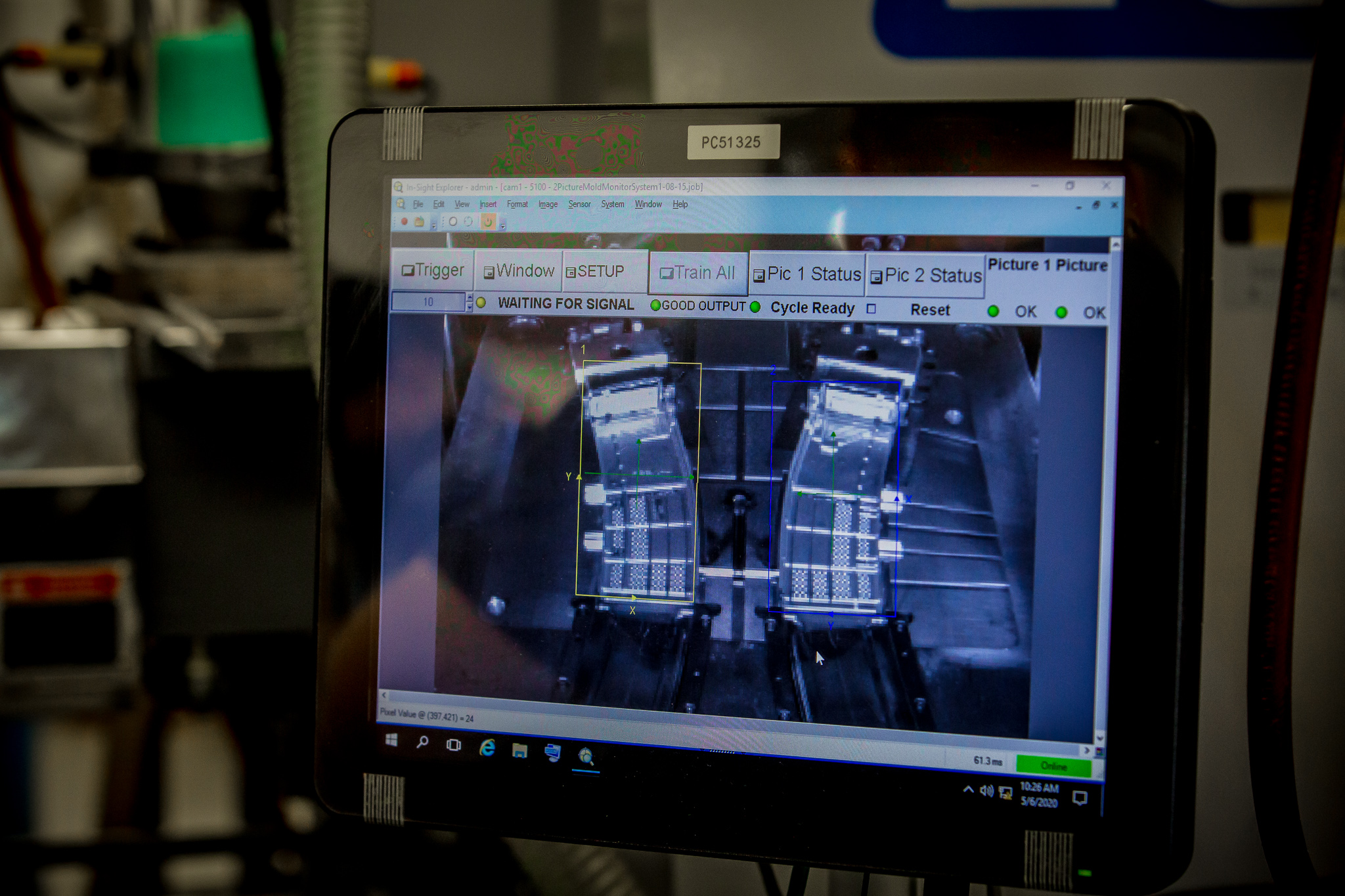

Executool operates in a clean environment, with a climate-controlled atmosphere. Each press area houses the necessary support equipment, including dryers, granulators, water/oil temperature controllers, robotic sprue pickers and part pickers. All presses are equipped with vacuum material loaders with sight glass controls and portable drying systems. Moisture analysis readings are taken and recorded to assure dry material. First-article inspection and in-process dimensional inspections are completed using Avant OGP video measuring system. Statistical process controls are offered on all production runs. Highly trained quality assurance personnel perform all inspections.

After a new tool or mold passes our sampling and approval process to part print, it is ready for production. The number of parts a mold will produce is determined by each customer’s end demand. These volumes can range from a few thousand to millions of parts per year. Each of our parts is assigned a full quality inspection plan, with a responsible leader from each of our key departments: tooling, engineering, quality and processing. These leaders work together to deliver the highest-quality part that meets and exceeds your needs. Some quality requirements require us to run plastic parts with tolerances of up to .0004″.

Executool Offers:

- Mold sampling

- Mold troubleshooting

- First-article inspection

- Full quality inspection plan

- Low volume short runs for JIT shipments

- High-volume production runs

- Certified-part production runs

- Consignment production runs

- Packaging

- Material lot trace ability

- Material certificates per shipment

- Assembly