Engineering and Production Capabilities

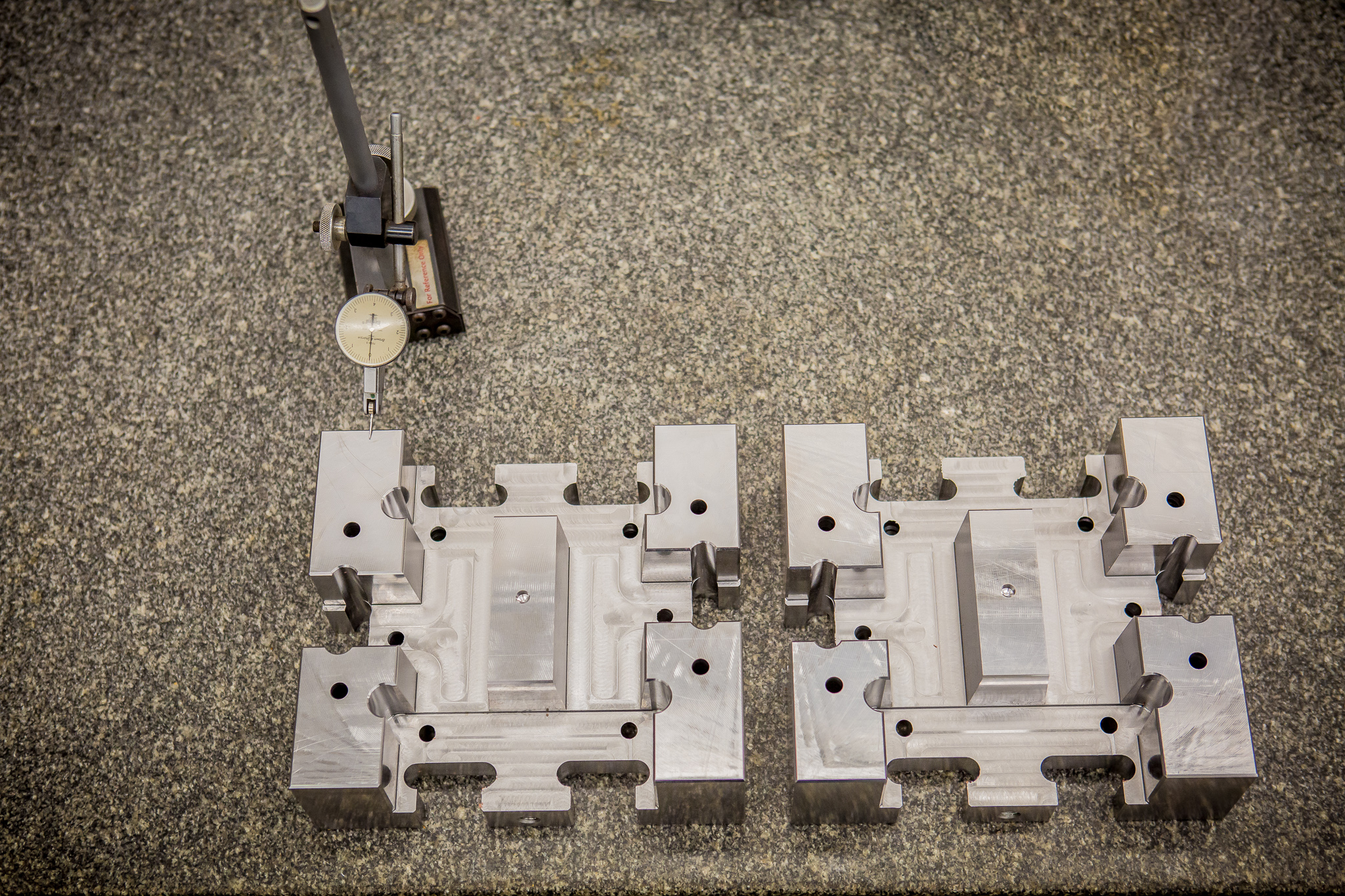

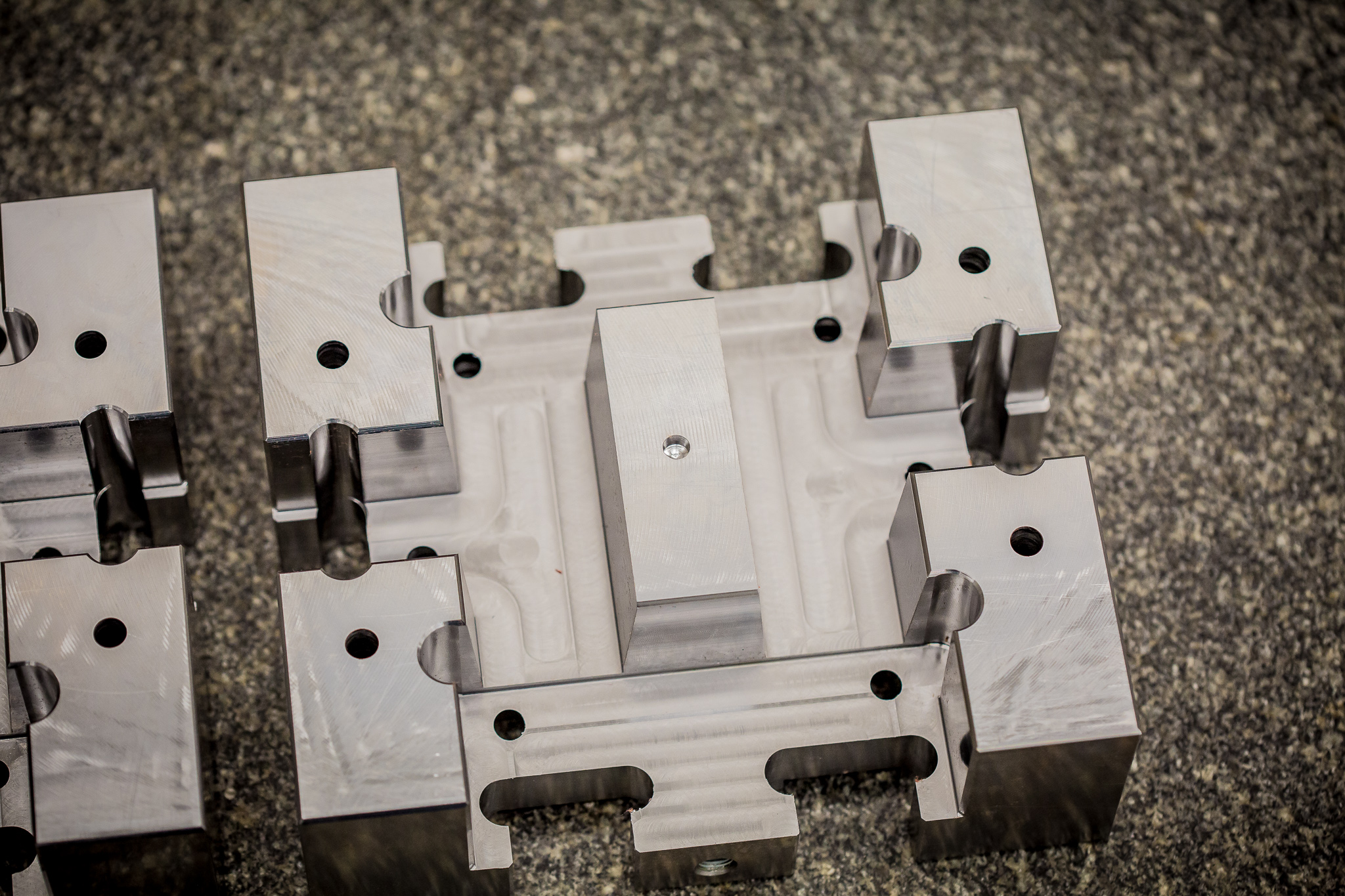

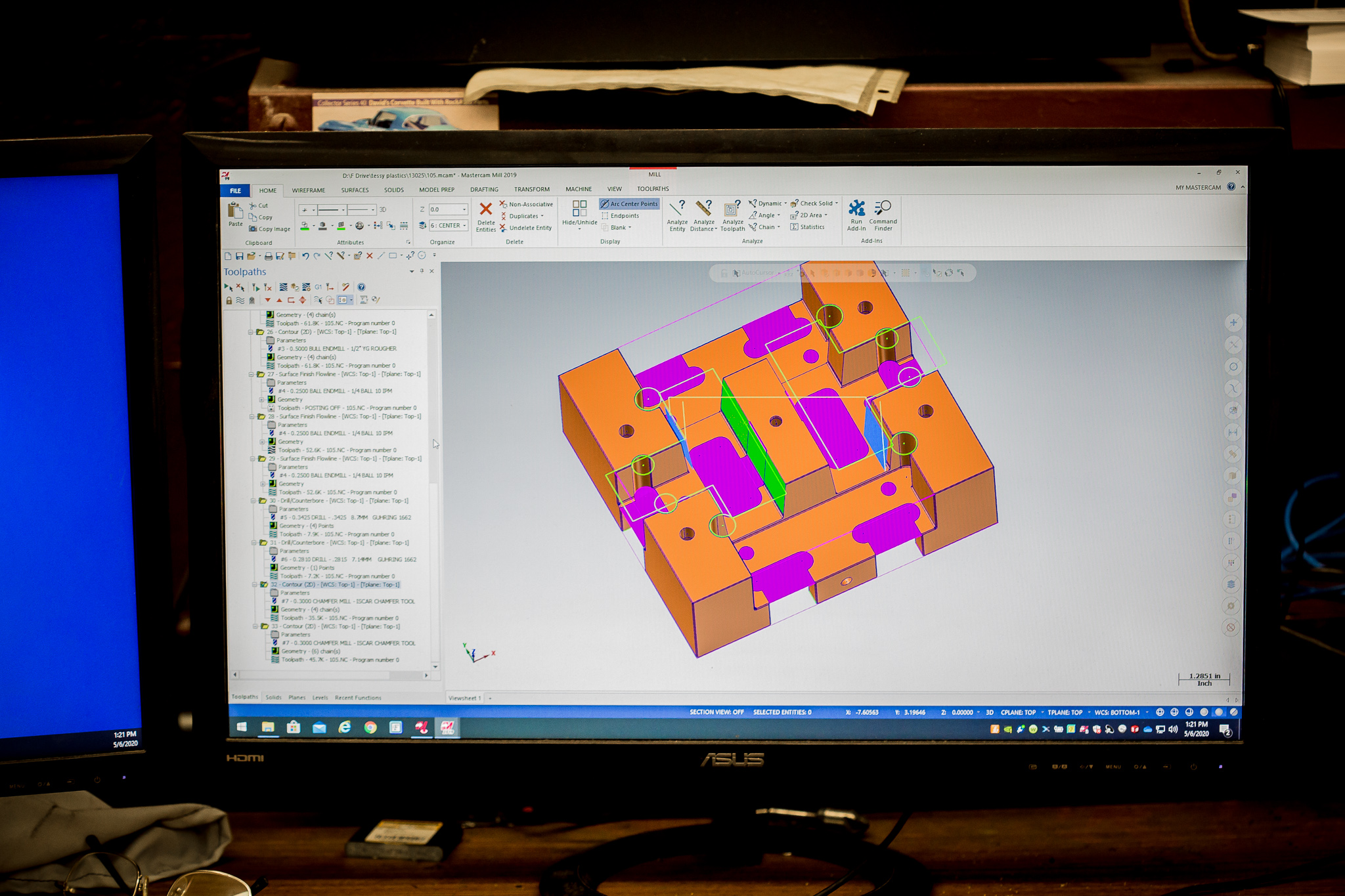

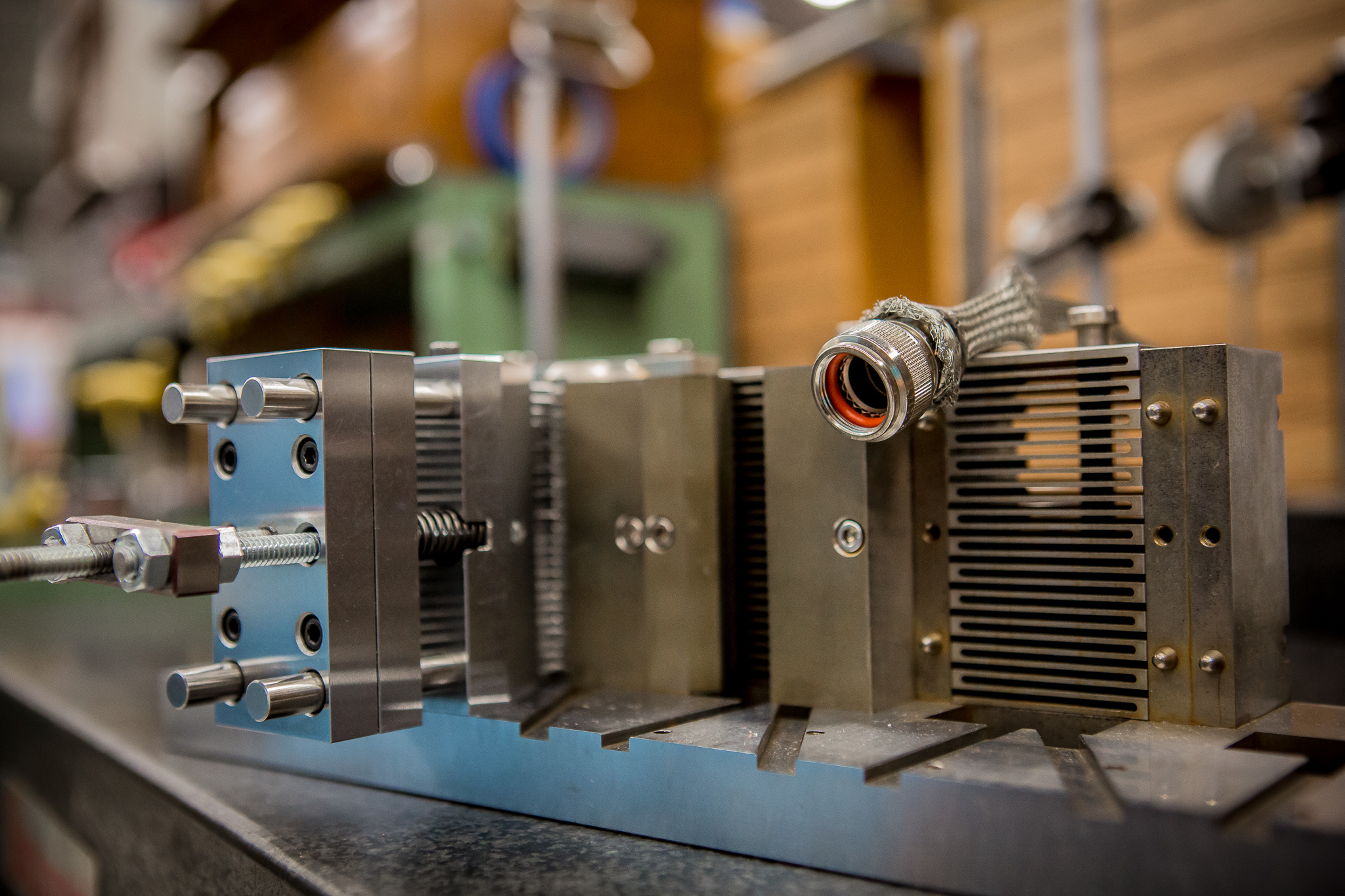

Executool’s Tooling Department specializes in complete manufacturing of close tolerance plastic and metal injection molds. We offer Class A high-production multi-cavity hot manifold molds to single-cavity prototype tooling.

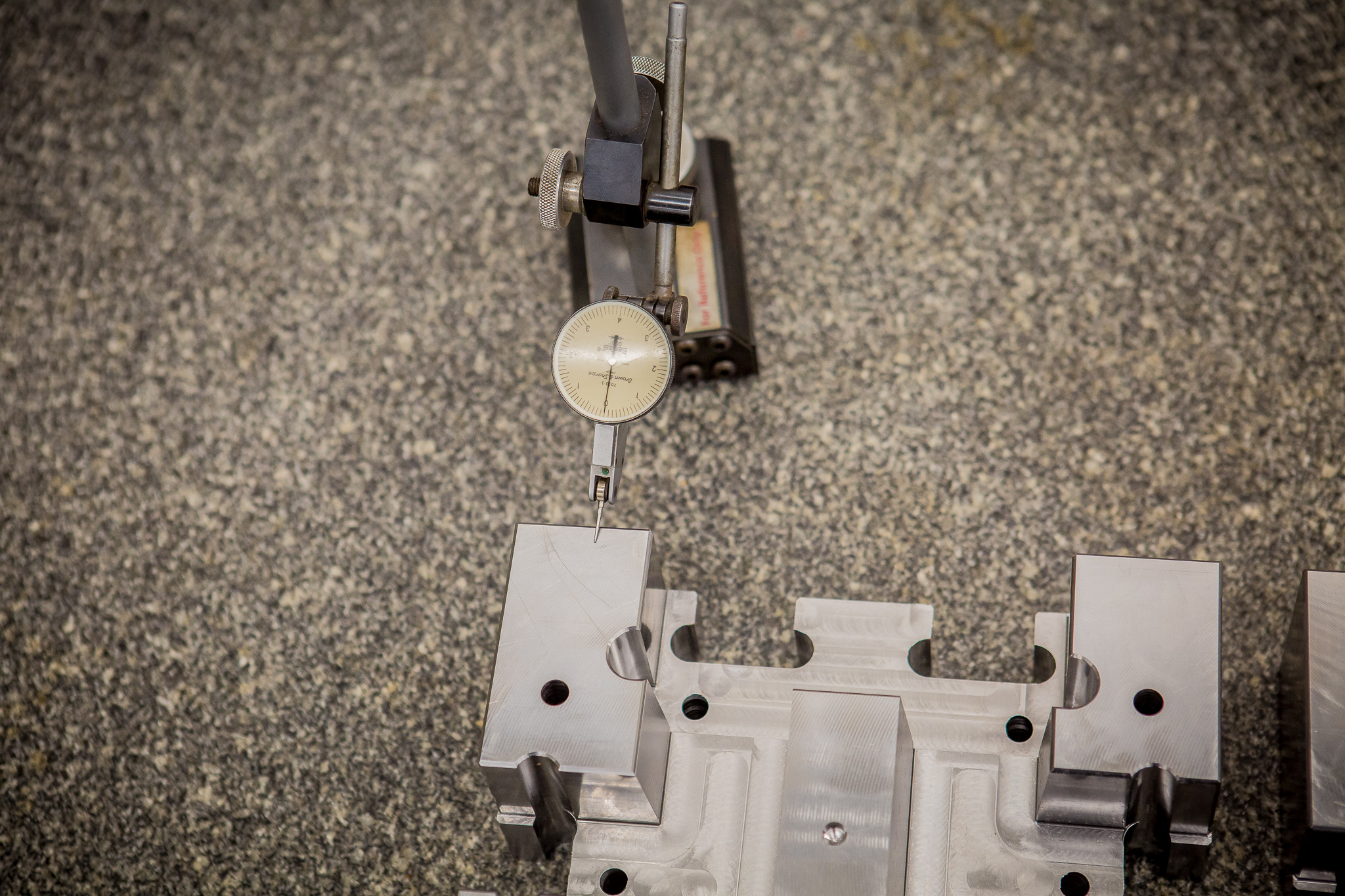

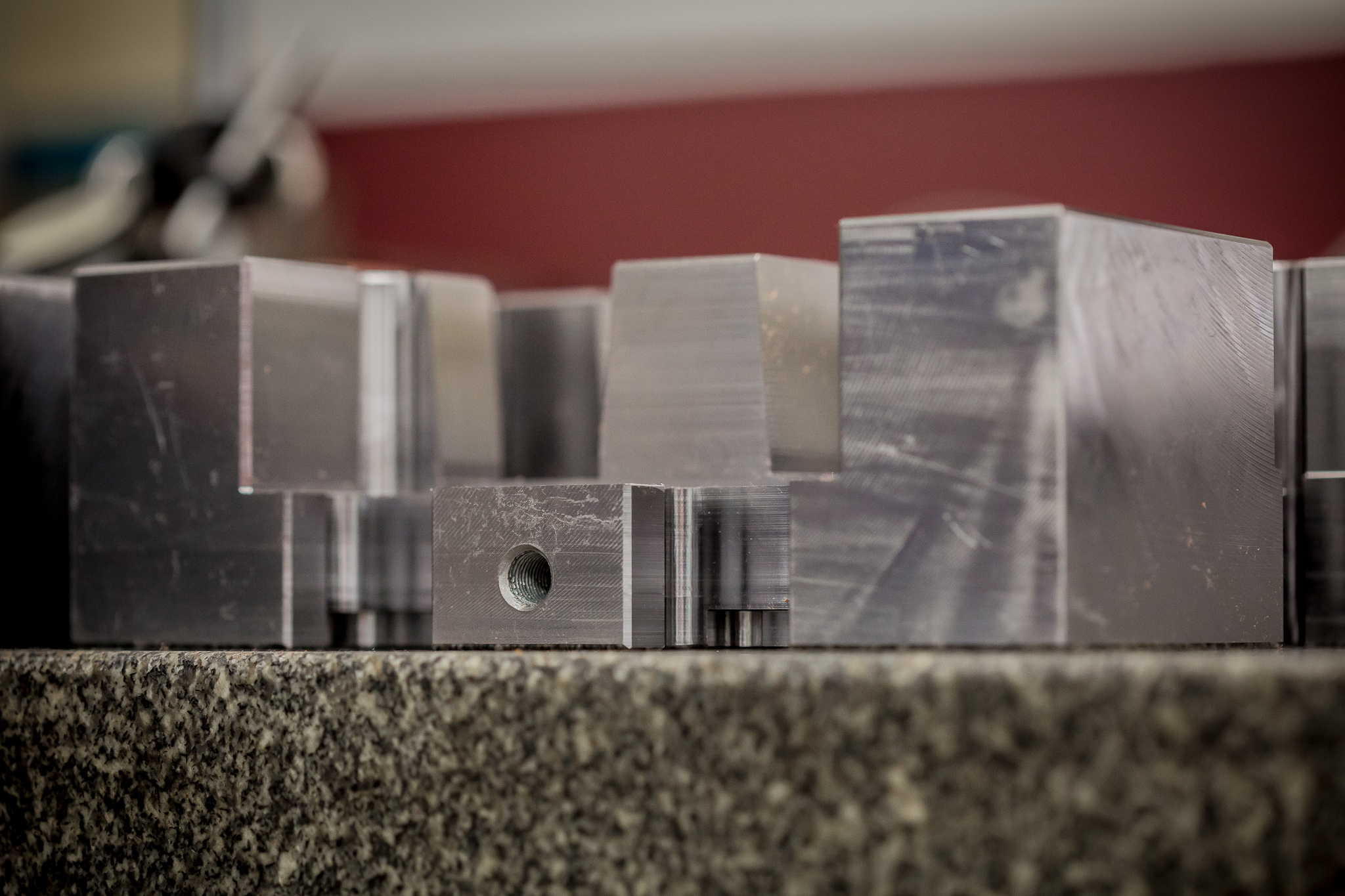

Our world-class tooling facility – approximately 18,000 sq. ft. of climate controlled manufacturing space is ISO 9001:2015 and ISO 13485:2016 certified. Executool is staffed by highly skilled craftsmen who build quality metal components with precision and attention to detail. Serving the automotive, computer, electronics, medical, pharmaceutical and general markets, our toolmakers can hold tolerances of up to .00002 per inch in laminated tooling.

At Executool, our high-quality, cutting-edge equipment meets all of the industry’s established standards, and we consistently meet our customers’ delivery requirements/timelines. Our mission: to get it right the first time. Our QA personnel can provide additional inspection certification, if desired.

We can also manage your foreign tool builds. With several partnerships with tooling facilities in Hong Kong, Taiwan and other Asian manufacturing centers, we can offer lower tooling costs, without sacrificing quality. Executool will design your tools, consign overseas builds, import tools and handle all shipping/duties/bonds/insurance when shipping tools back to the United States. Tools are sampled and conditioned to meet first-article inspections based on your requirements.